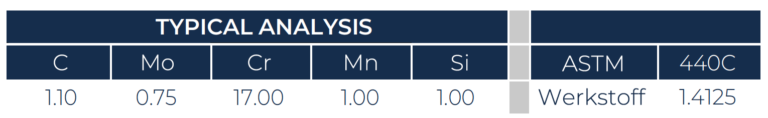

440C STEEL

Material available in round and flat sections

440C is a martensitic stainless steel of high carbon and chromium content capable of full hardening response after oil quenching or air cooling.

Applications

The outstanding wear resistance of 440C combined with it’s moderately good corrosion resistance make it an excellent candidate for bearings, bushings, valve components, cutlery, pump parts, seaming chucks and rolls.

Annealing

For maximum softness 440C should be heated slowly to 850° / 900° C equalized, and very slowly furnace cooled to 540° C followed by cooling in air. Typical fully annealed hardness is 229 / 255 Brinell. Intermediate process annealing can be accomplished by heating uniformly to 730 / 760° C followed by air cooling. Since typical hardness will be above 255 Bhn, the full annealing process is preferred.

Stress Relieving

Heat to 650 / 700 C. Hold for 2 – 4 hours and furnace cool.

Hardening

Heat slowly to 101 O / 1060° C and oil quench. Smaller sections can be air cooled. As quenched hardness in the range of Rockwell “C” 60 / 61 is possible.

Tempering

Tempering 440C in the range of 180 / 230° C is recommended to develop full -working hardness in the range of Rockwell “Cn 57 I 59.

TYPICAL HARDNESS AFTER TEMPERING

Temperature °C | Rockwell C | Brinell |

|---|---|---|

| 150 | 60-61 | 614 |

| 180 | 57-59 | 578 |

| 200 | 57-58 | 578 |

| 260 | 56 | 555 |

| 320 | 55-56 | 555 |

| 430 | 56 | 555 |

| 540 | 57-59 | 578 |

| 650 | 38-39 | 352 |

TYPICAL MECHANICAL PROPERTIES

These curves indicate typical values obtained from standard test specimens air cooled from 1030°C and double tempered at 600°C.

TEMPERING °C | HARDNESS RC | U.T.S KSI | TENSILE YIELD KSI | % ELONGATION IN 50MM | % REDUCTION OF AREA | COMPRESSIVE STRENGTH KSI |

|---|---|---|---|---|---|---|

| Annealed As Quenced | 98 | 110 | 70 | 15 | 30 | |

| 1040 | 61/62 | |||||

| 260 | 57 | 265 | 230 | 350 | ||

| 320 | 53/56 | 267 | 230 | 338 | ||

| 430 | 54 | 267 | 230 | 330 | ||

| 540 | 43/45 | 248 | 200 | 321 | ||

| 650 | 38/39 | 150 | 130 | 181 |