2083 PLASTIC TOOL STEEL

Material available in round and flat sections

Corrosion-resistant mould steel, highest cleanliness and good polishability, good machinability, low distortion through hardening steel, high hardenability, high wear resistance.

Applications

Suitable for moulds, tooling and inserts for processing plastics with corrosive reactions, moulds and pressure tools

Annealing

Pack in spent carburising mixture or other inert media in a sealed container to prevent decarburisation and excessive scaling. Heat slowly to 850°C / 880°C and hold at temperature for sufficient time to achieve uniformity. Cool at not faster than 25°C per hour to 650°C and withdraw. Correctly annealed the tools or stock should have a maximum hardness of 241 HB.

Stress Relieving

Heat to 650°C / 700°C. Hold for 2-4 hours and furnace cool.

Hardening

Temperature | 1010°C / 1030°C air cool | 970°C / 990°C oil quench |

|---|---|---|

| 200°C/210°C | 710-760 HV (60-62 HRC) | 670-735 (59-61 HRC) |

| 240°C/250°C | 670-735 (59-61 HRC) | 650-600 HV (58-56 HRC) |

| 520°C/550°C | 625-735 (57-61 HRC) | 535 -600 HV (52-56 HRC) |

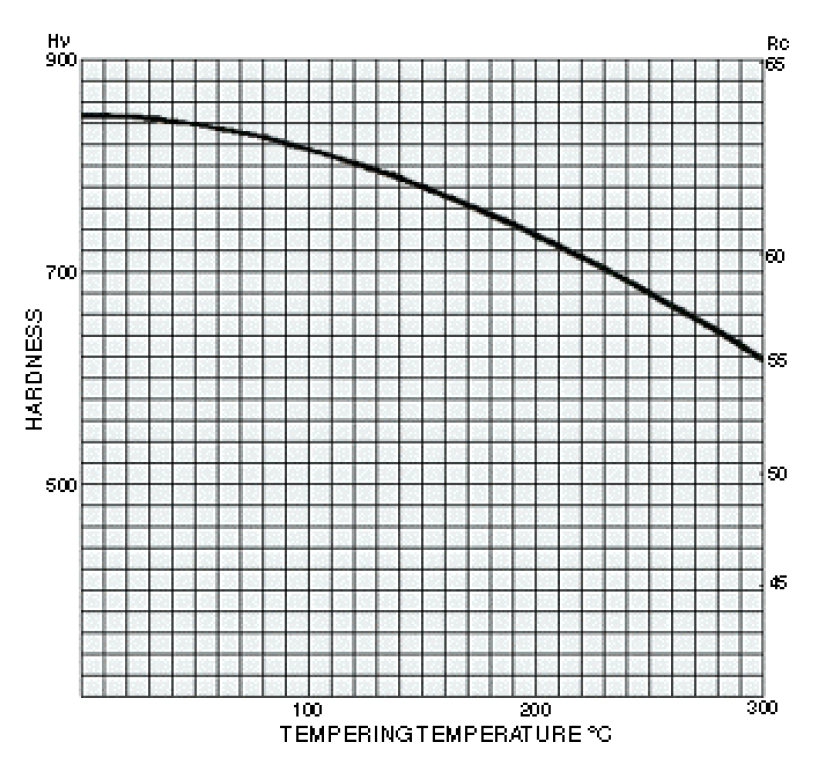

Tempering

Slow heating to tempering temperature immediateliy after hardening. Time in furnace 1 hour for each 20 mm of workpiece thickness but at least 2 hours. Tempering must be repeated at least twice at a temperature 30°C lower than the previous.

TYPICAL HARDNESS AFTER TEMPERING

Tempering Temperature | HRC |

|---|---|

| 100°C | 56 |

| 200°C | 55 |

| 300°C | 52 |

| 400°C | 51 |

| 500°C | 52 |

| 600°C | 40 |