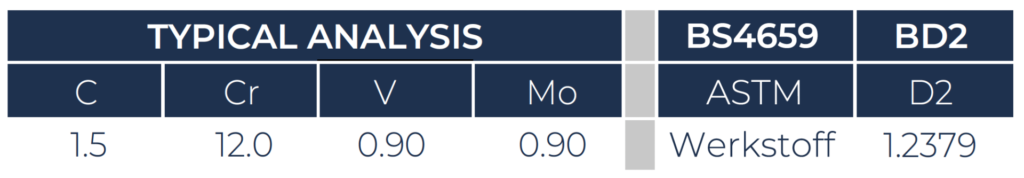

D2 COLD WORK TOOL STEEL

Material available in round and flat sections

D2 is a high carbon, high chromium cold work tool steel which shows improved toughness and machinability with little sacrifice in wear resistance. The steel can be air or vacuum hardened and so finds application where distortion in heat treatment must be kept to a minimum. The steel can also be used for certain hot work applications where the time of contact with the work piece is short and where resistance to abrasion is important.

Applications

Typical uses of D2 are blanking, moulding, forming, thread rolling and drawing dies, shear blades, gauges and burnishing rolls.

Annealing

Pack in spent carburising mixture or other inert media in a sealed container to prevent decarburisation and excessive scaling. Heat slowly to 850°C / 880°C and hold at temperature for sufficient time to achieve uniformity. Cool at not faster than 25°C per hour to 650°C and withdraw. Correctly annealed the tools or stock should have a maximum hardness of 241 HB.

Stress Relieving

Heat to 650°C / 700°C. Hold for 2-4 hours and furnace cool.

Hardening

Temperature | 1010°C / 1030°C air cool | 970°C / 990°C oil quench |

|---|---|---|

| 200°C/210°C | 710-760 HV (60-62 HRC) | 670-735 (59-61 HRC) |

| 240°C/250°C | 670-735 (59-61 HRC) | 650-600 HV (58-56 HRC) |

| 520°C/550°C | 625-735 (57-61 HRC) | 535 -600 HV (52-56 HRC) |

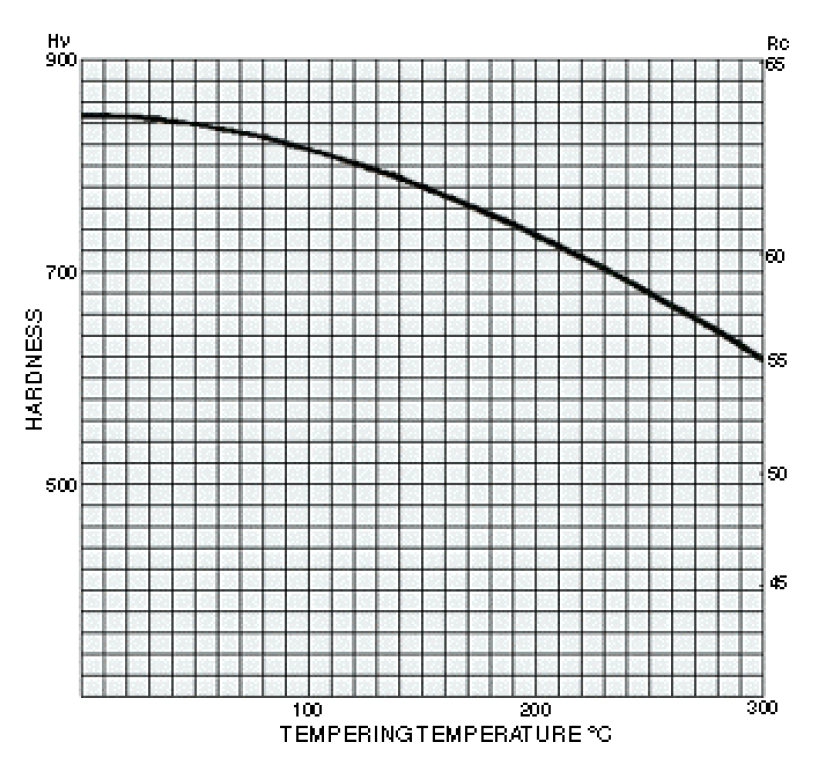

Tempering

Heat to 200°C / 250°C for a minimum of one hour. A hot air circulation furnace may be used. Tempering within this range will be suitable for most working cold working applications, but not for hot dies, tempering at 520°C / 550°C is recommended.

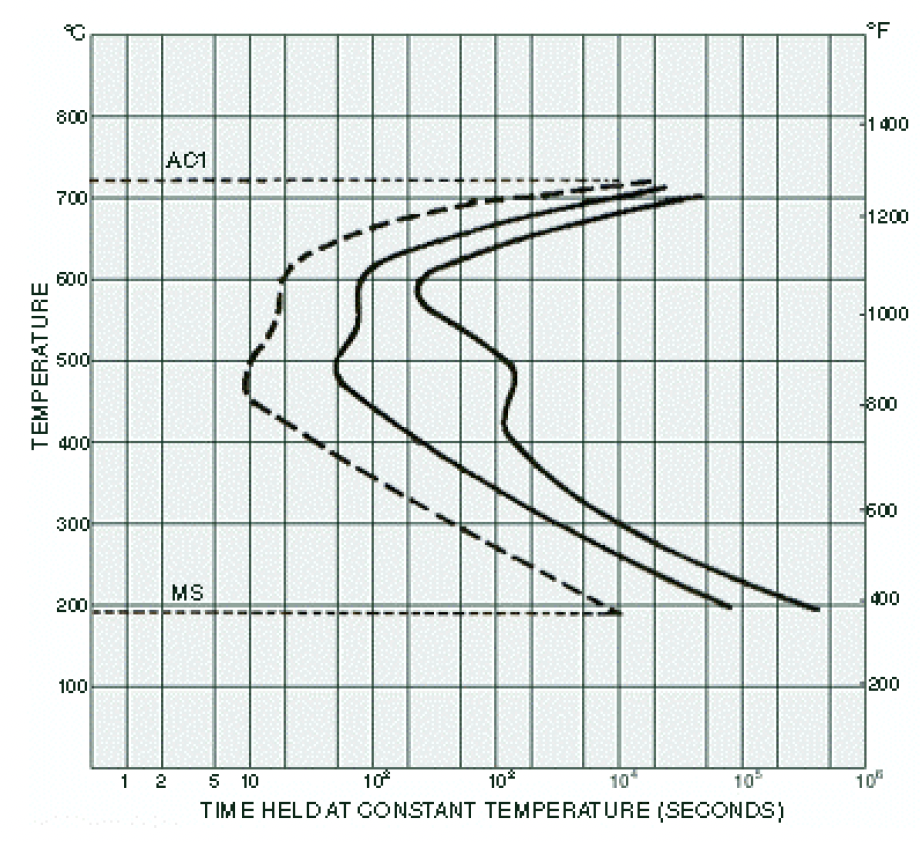

Isothermal Transformation

The diagram illustrates the time required for transformation of austenite to commence and it may be usefully employed in determining the correct temperatures and holding times for interrupted quenching treatments.

(Austenitised at 1010°C)