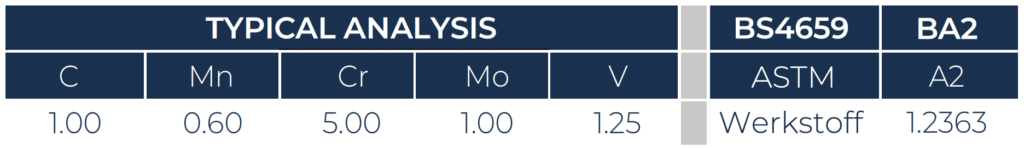

A2 COLD WORK TOOL STEEL

Material available in round and flat sections

A2 is a 5% Chromium steel which air hardens to provide high hardness with minimum dimensional change. It has impact and wear resistance characteristics intermediate between the oil hardening Carbon Manganese steels and the conventional High Carbon High Chromium types.

Applications

This steel is particularly useful as intricate dies where minimal dimensional change is required in heat treatment but it is also widely used for blanking tools and dies, gauges, shear blades for cold light sections, cold heading tools and trimming and stamping dies.

Annealing

To prevent excessive scaling or decarburisation pack with a suitably inert material in a sealed container. Heat to 850°C / 870°C, hold at temperature for a sufficient time to ensure uniformity then cool at less than 25°C per hour to 650°C. The parts may then be cooled in air. Correctly annealed this steel should have a hardness not greater than 235 HB.

Stress Relieving

Heat to 650°C. Hold for 2-4 hours and furnace cool.

Hardening

Before heat treatment, sufficient machining should be carried out to remove surface decarburisation. Where possible hardening should be carried out in neutral salt baths or controlled atmosphere furnaces. Preheat slowly to 750°C / 800°C then transfer to a bath or furnace operating at 950°C /980°C soaking for twenty minutes plus ten minutes per inch of section. Cool in still air.

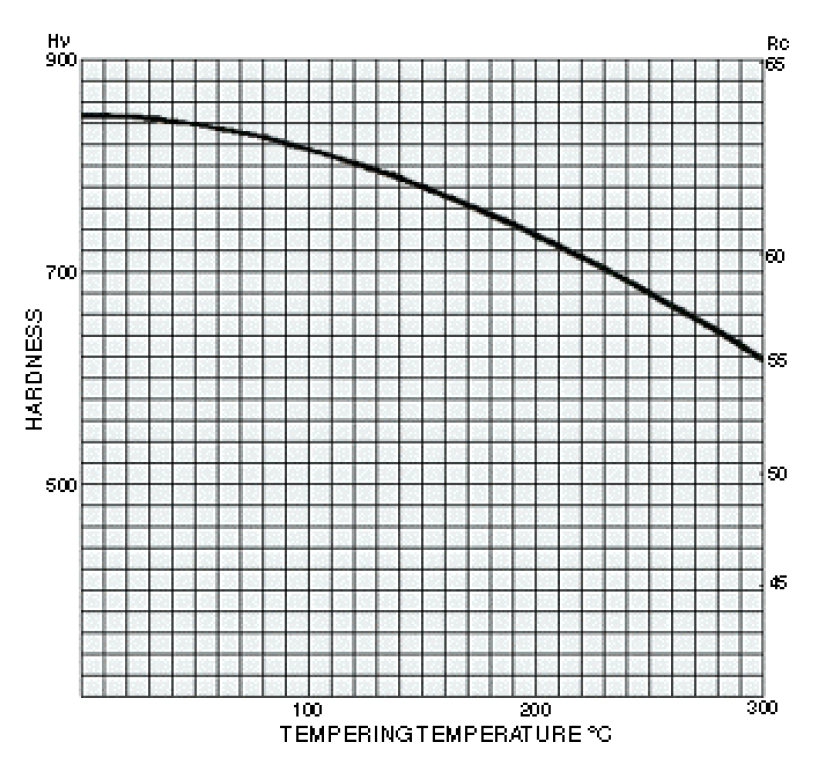

Tempering

Tempering should be carried out immediately following completion of the quenching operation. Heat to within the 175°C / 225°C range and hold at temperature for a minimum period of one hour. Increased toughness will be obtainable by tempering within the 350°C/ 400°C range but this will be at the expense of hardness. The tempering curve given provides typical data obtained by cooling from 970°C.

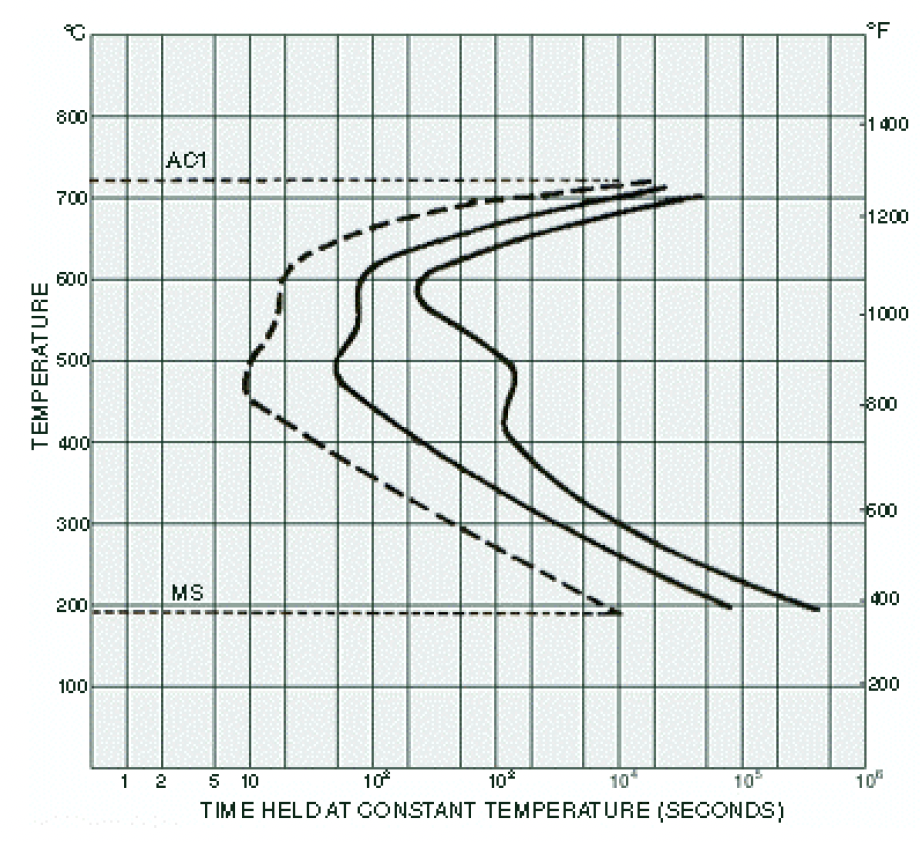

Isothermal Transformation

The diagram illustrates the time required for transformation of austenite to commence and it may be usefully employed in determining the correct temperatures and holding times for interrupted quenching treatments.

(Austenitised at 975°C)