S1 COLD WORK TOOL STEEL

Material available in round and flat sections

S1 is a medium carbon, oil hardening, shock resisting steel that may be employed in circumstances where exceptional resistance to shock and repeated transverse stress is required. Heat treatment can produce a high degree of cutting hardness with great toughness. The steel is deep hardening permitting many regrinds before the tool is worn out.

Applications

Typical uses are hand and pneumatic chisels, heavy duty punches, screwdriver bits, shear blades, boilermakers tools, swaging dies, pharmaceutical punches and dies and cold mandrels.

Annealing

To prevent excessive scaling or decarburisation pack in sealed container with a suitably inert material. Heat to 790°C / 820°C, hold until uniform then slow cool at not faster than 25°C per hour to 650°C followed by air cooling. Properly annealed S1 should have a maximum hardness of 235 HB.

Stress Relieving

Heat to 650°C / 700°C. Hold for 2-4 hours and furnace cool.

Hardening

Preferably preheat larger and intricately shaped tools to 650°C / 700°C, raise quickly to 900°C / 920°C and quench in oil. Removal from oil whilst still hot, at approximately 150°C / 180°C, will minimise the risk of cracking. Tools of intricate design and those possessing changes in section thickness may with advantage be quenched into a salt bath at 540°C / 560°C, allowed to equalise, and quenched in oil. For most purposes tempering for one hour at 230°C is sufficient, but for extra toughness 650°C may be used with a lowering of hardness.

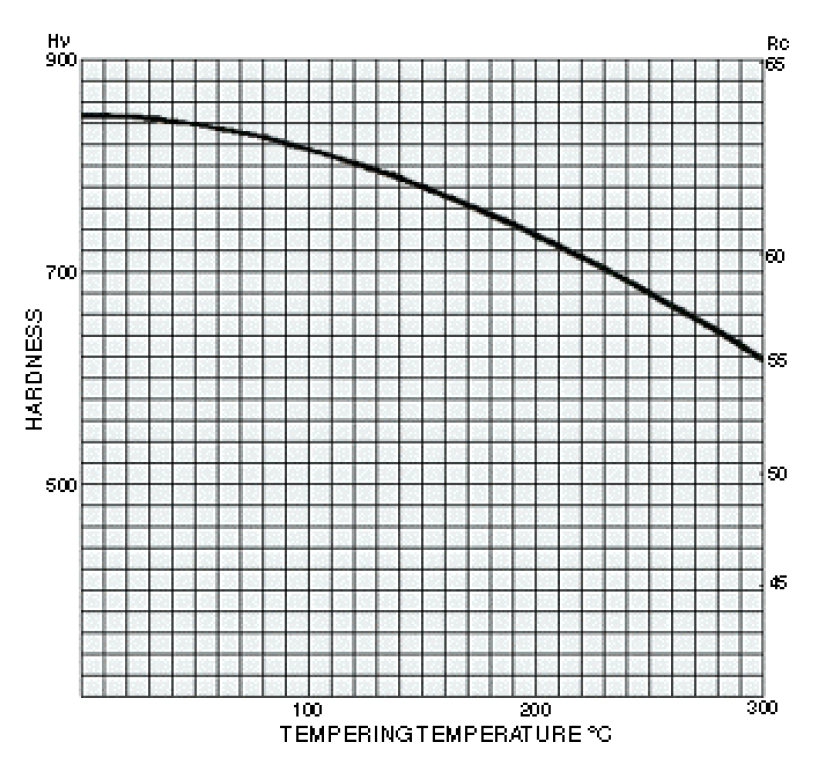

Tempering

For most purposes tempering for one hour at 230°C is sufficient, but for extra toughness 650°C may be used with a lowering in hardness.

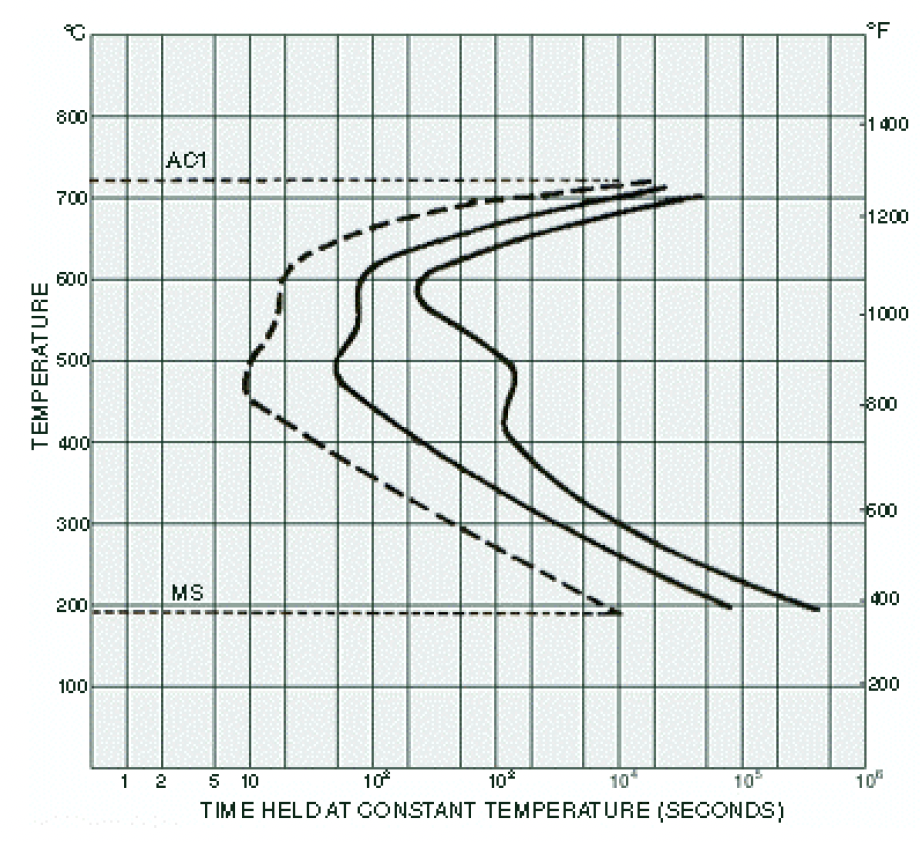

Isothermal Transformation

The diagram illustrates the time required for transformation of austenite to commence and it may be usefully employed in determining the correct temperatures and holding times for interrupted quenching treatments.

(Austenitised at 890°C)