01 COLD WORK TOOL STEEL

Material available in round and flat sections

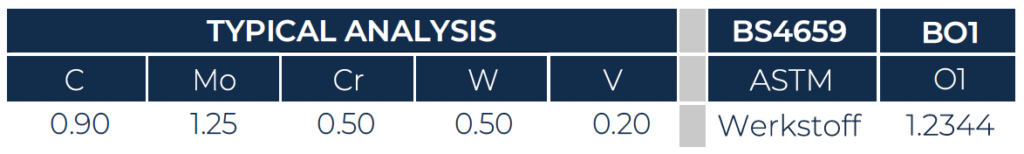

O1 is a standard oil hardening, carbon manganese tool steel possessing excellent dimensional stability in heat treatment. The vanadium content of O1 offers an advantage over other similar steels by promoting a uniformly fine grain size in tools of varying sections and by providing an added safeguard against the effects of overheating.

Applications

Typical uses of O1 include gauges, taps, cold punches, cold blanking and forming dies, reamers, drill bushes, straight edges, deep drawing and needle dies, engraving dies, shear blades, ground flat stock, templates and general wearing parts for machines.

Annealing

Tools should be protected from excessive scaling or decarburisation by packing in a suitable inert material in a sealed container. Heat to 770°C / 790°C and hold for sufficient time to ensure uniformity then cool slowly at 20°C per hour to 650°C. The tools may then be withdrawn and air cooled. This treatment should result in a hardness of 229 HB maximum.

Stress Relieving

Heat to 650°C /700ºC . Hold for 2-4 hours and furnace cool.

Hardening

Before heat treatment, sufficient machining should be carried out to remove surface decarburisation. Preheat thoroughly to 650°C / 700°C and then raise more rapidly to 780°C / 790°C in a controlled atmosphere furnace or, preferably, a neutral salt bath. Quench in oil. A useful alternative is box hardening using spent charcoal placed away from the working faces. Larger sections may be hardened from 810°C / 820°C.

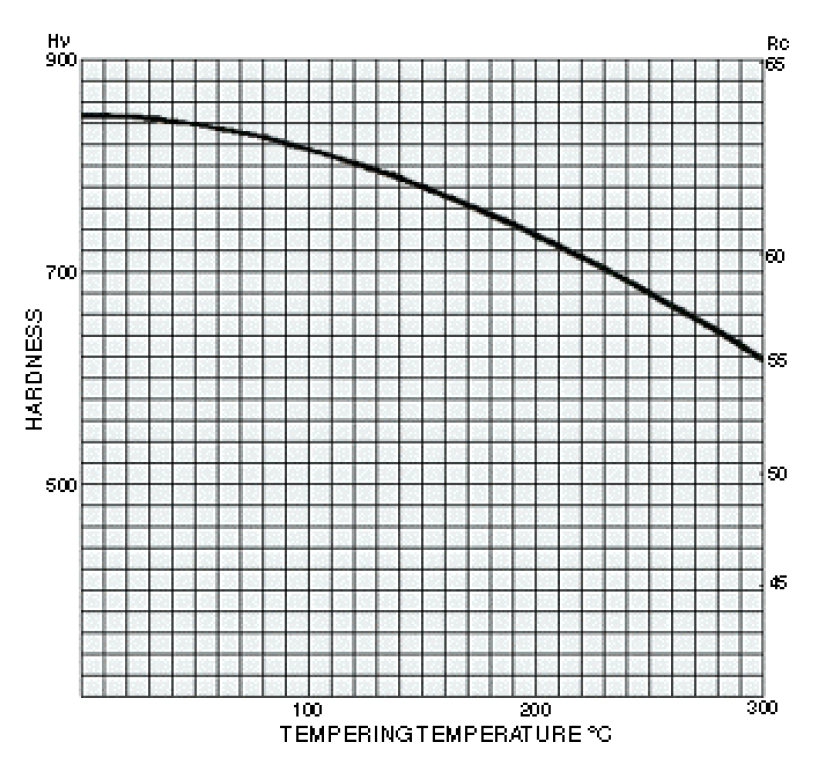

Tempering

Tools must be tempered as soon as possible following completion of the quenching operation. Heat to within 190°C / 210°C and hold for a minimum period of one hour. Longer times are advised for larger sections. The tempering curve values indicates typical hardness values obtained from oil quenching test samples from 790°C.

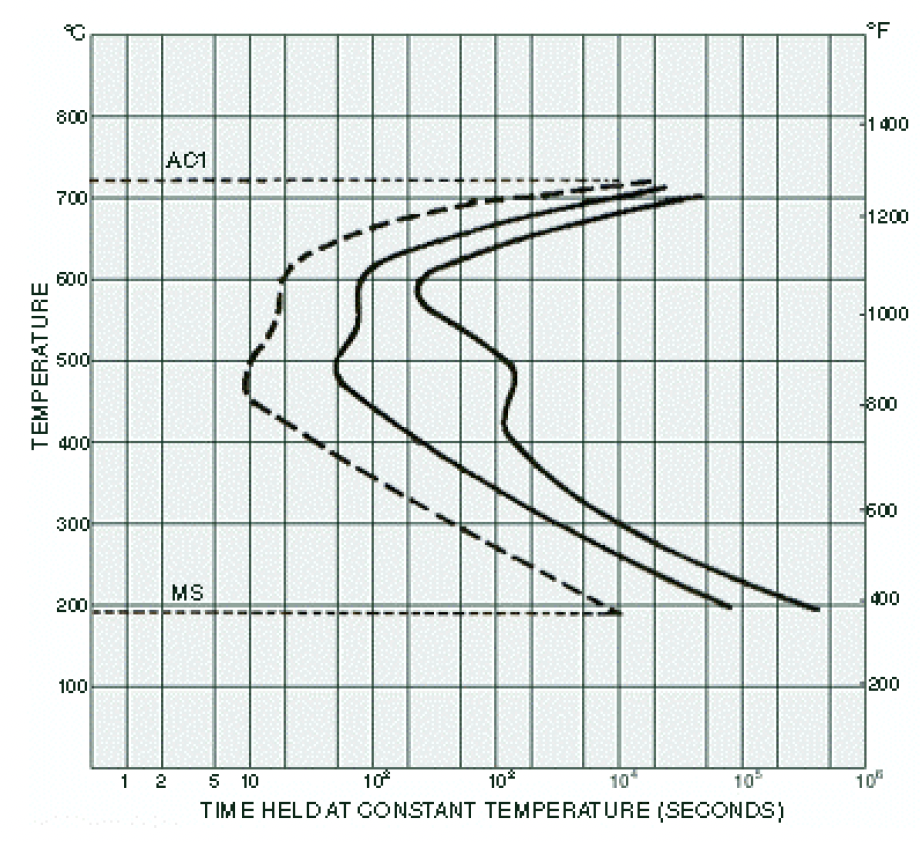

Isothermal Transformation

The diagram illustrates the time required for transformation of austenite to commence and it may be usefully employed in determining the correct temperatures and holding times for interrupted quenching treatments.

(Austenitised at 800°C)