H13 Hot Work Tool Steel

Material available in round and flat sections

H13 is an air hardening 5% chromium die steel used for a range of applications. The higher vanadium content ensures increased resistance to heat checking and provides improved all round properties at elevated temperatures. It has excellent toughness characteristics and like the other 5% chromium die steels, may be water cooled in service.

Applications

H13 is particularly suitable for aluminium , zinc and magnesium die casting tools where resistance to heat checking is of prime importance. Other uses include extrusion dies and mandrels, hot piercing tools, hot blanking and forging dies, shear blades, hot punches and die inserts.

Annealing

If possible pack in a suitable sealed container with spent carburising mixture or cast iron chippings. Heat to 850°C / 870°C, hold for sufficient time to ensure uniformity, then cool no faster than 25°C per hour to 650°C followed by air cooling. This should result in a hardness of 235 HB maximum.

Stress Relieving

Heat to 650°C / 700°C. Hold for 2-4 hours and furnace cool.

Hardening

Before heat treatment, sufficient machining should be carried out to remove surface decarburisation. Preheat thoroughly at 750°C / 800°C and then raise more rapidly to 1000°C / 1020°C in a controlled atmosphere furnace or preferably, a neutral salt bath. Cool in air. A useful alternative is box hardening using spent charcoal placed away from the working surfaces.

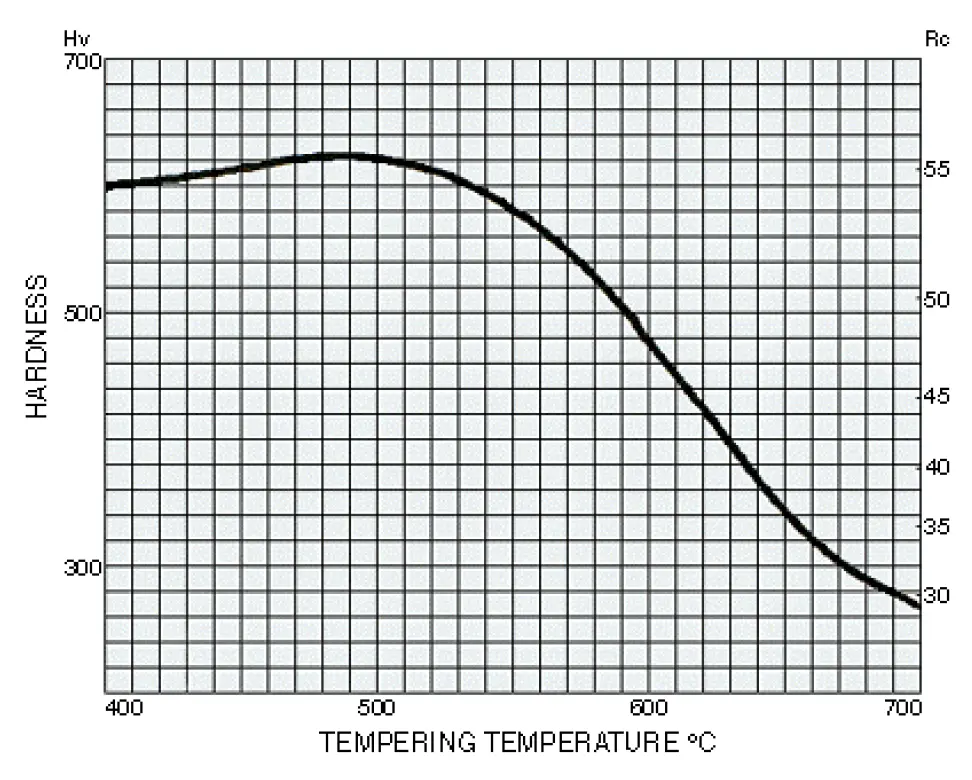

Tempering

Tempering should be carried out as soon as possible following completion of quenching. Heat to within the 550°C / 650°C range soaking at temperature for one to three hours according to section. A second temper holding at temperature for at least one hour is essential and care must be taken to ensure that the tools cool to room temperature between cycles. For applications where thermal fatigue is of prime importance a third tempering operation is recommended. The curve given provides typical hardness values obtained on air cooling from 1020°C and double tempering.

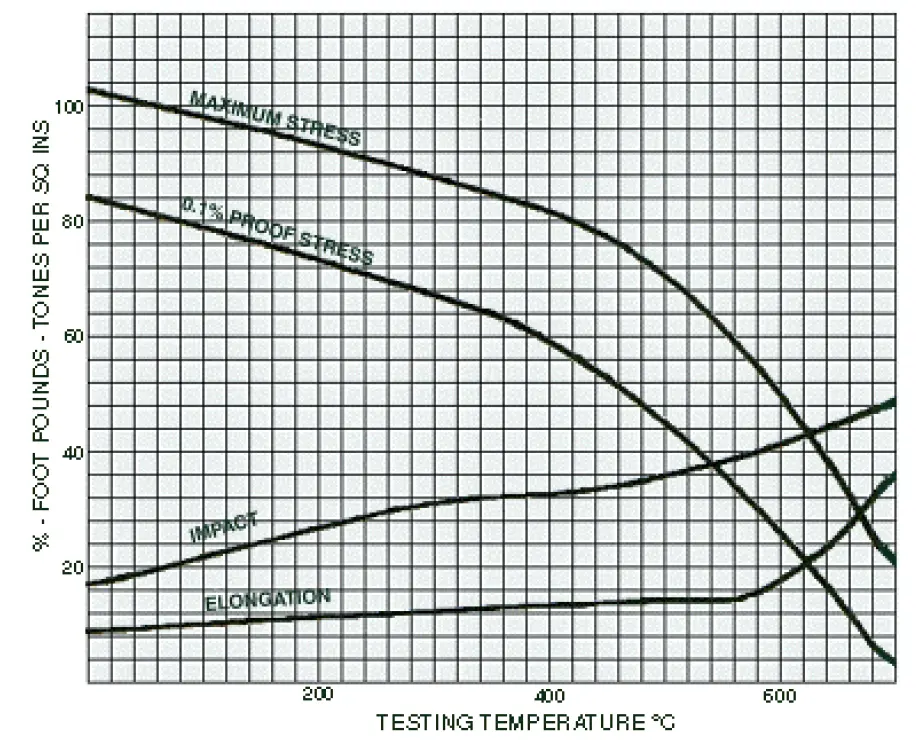

Elevated Temperature Properties

These curves indicate typical values obtained from standard test specimens air cooled from 1030°C and double tempered at 600°C.

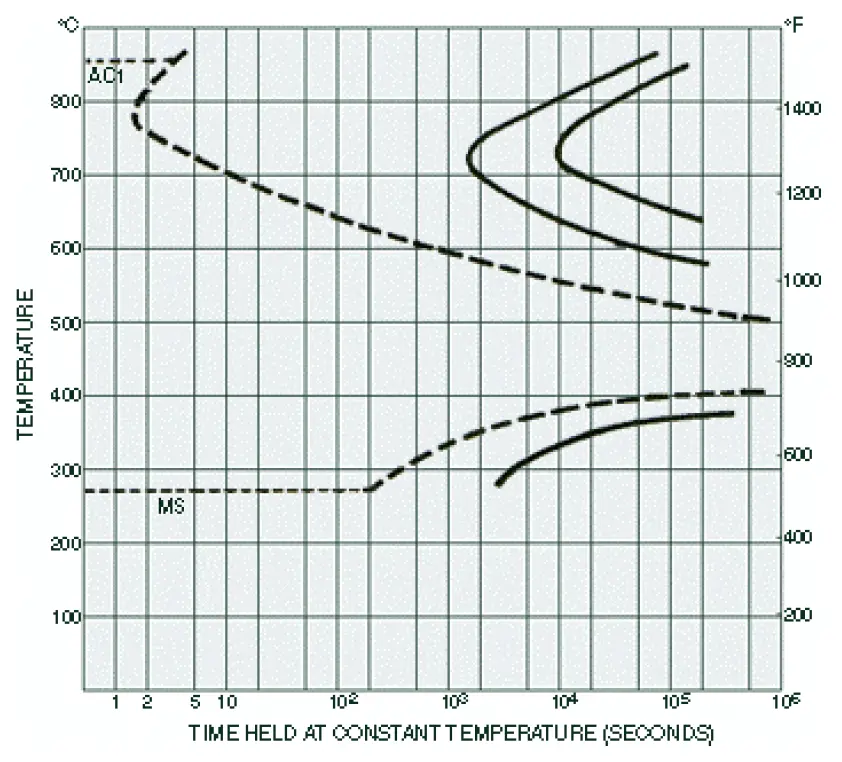

Isothermal Transformation

The diagram illustrates the time required for transformation of austenite to commence and it may be usefully employed in determining the correct temperatures and holding times for interrupted quenching treatments.