Tool Steel is a special Steel that is known for its High Hardness and wear resistance properties and its ability to retain its sharp edge during the manufacturing process.

This steel also exhibits good levels of toughness considering the high nature of the alloying elements present. The majority of these steels need to be heat-treated to achieve their optimum metallurgical properties.

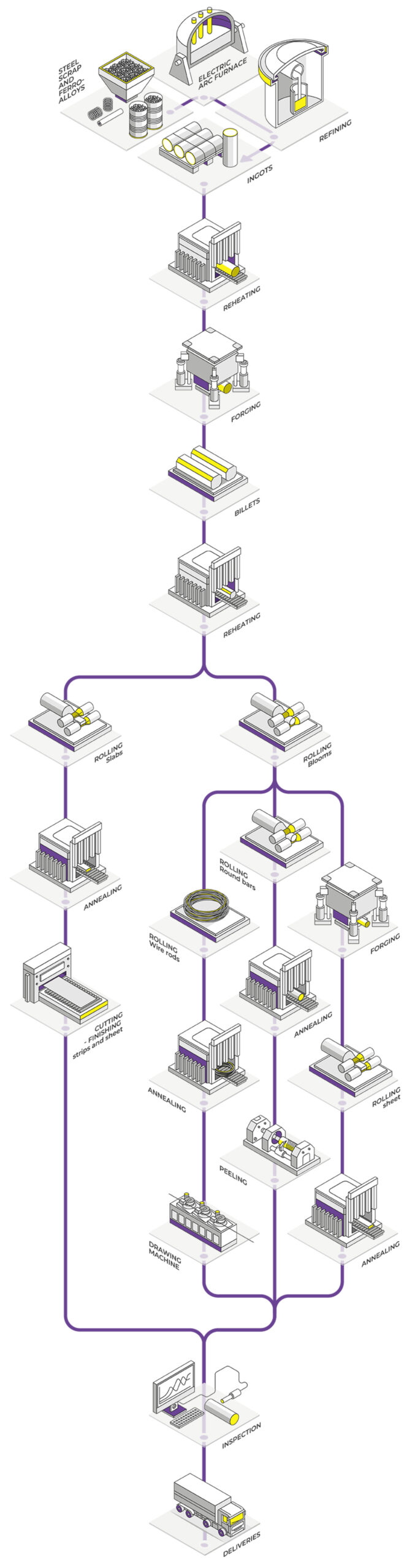

These steels can also undergo a further refining process known as Electroslag Remelting (ESR).

ESR is a secondary steelmaking process that uses an electric current to melt a consumable electrode, which then drips through a molten slag into a water-cooled mold, resulting in a refined, high-quality ingot. This process allows for precise control of chemical composition and solidification, leading to improved material properties.