For over 25 years, we are proud to be the sole exclusive agents and distributors in the UK and Ireland representing world renowned company Erasteel for High-Speed Steel and Powder Metallurgy steels.

Taylor Special Steels source all of their Powder Metallurgy steels from Erasteel.

Powder Metallurgy is a core technology at Erasteel with more than 50 years of experience. Based on its knowhow, Erasteel developed: ASP® Powder Metallurgy High-Speed Steel, for cutting tools, cold work tools, saws & knives, automotive components and wear resistant components.

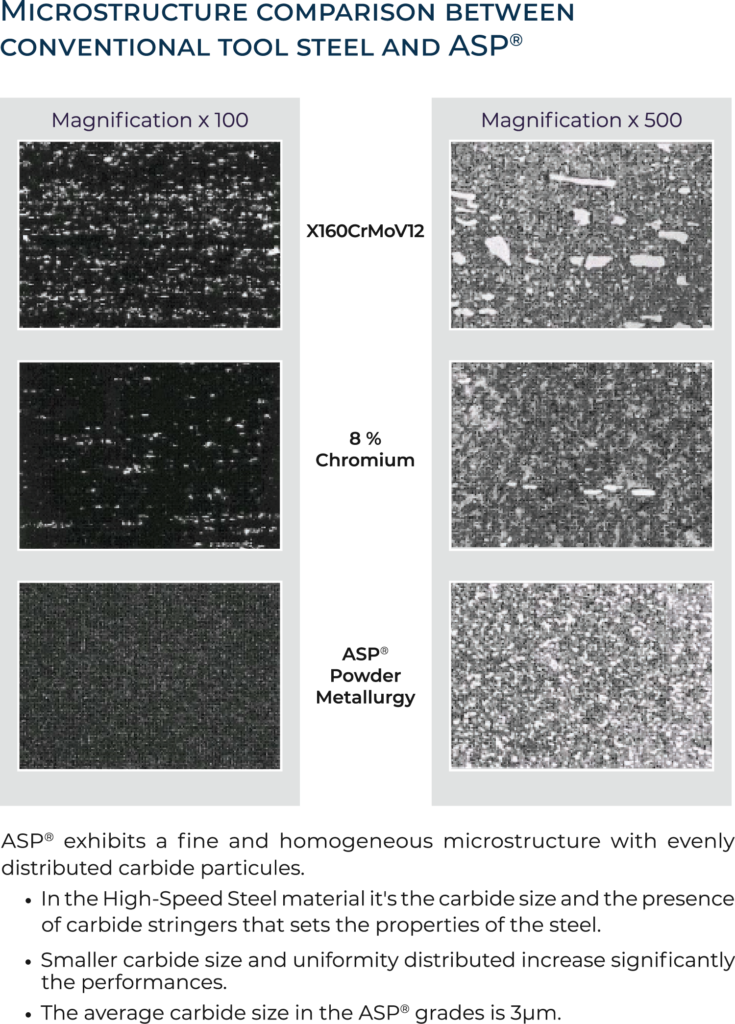

Powder Metallurgy can produce High-Speed Steels of higher strength than conventional techniques, but it also offers a possibility for production of materials of higher alloying content. This is an opportunity to obtain higher hardness and larger amounts of hard carbide particles in the steel. Both these factors will give higher wear resistance. By proper choice of steel grade (chemical composition) and heat treatment, a favorable combination of mechanical properties – that is, hardness, strength and wear resistance – can normally be obtained.

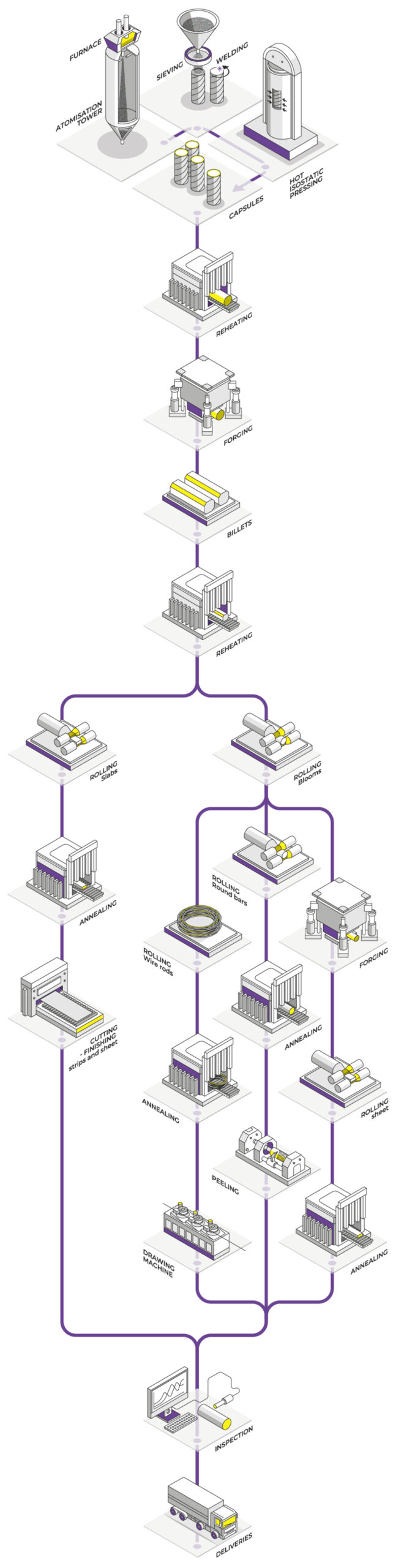

Erasteel is the leader of the Powder Metallurgy High-Speed Steel market thanks to its long experiences in powder atomization. Gas atomization is a process to manufacture high quality metal powders. During the gas atomization process, the molten steel is atomized thanks to inert gas jets into fine metal droplets which cool down during their fall in the atomizing tower. Metal powders obtained by gas-atomization offer a perfectly spherical shape combined with a high cleanliness level. After the atomization process, powders are collected in a capsule which is sealed and then compacted by Hot Isostatic Pressing (HIP). The semi-finished capsule is then further processed by forging, hot rolling and drawing or cold rolling into various product forms such as round and flat bars or profiled wire, sheets and strips.

Since its first atomization more than 50 years ago, Erasteel has not stopped its technological advances allowing to produce ASP® more and more efficient as ASP®2078 or ASP®2012.

The molten steel is poured from a big tundish which allows to run down a fine jet of molten steel into an atomization chamber. At the top of the chamber the steel is fragmented into a shower of steel droplets by high-speed gas jets. When the droplets have reached the bottom of the chamber, they have solidified. Each powder grain (droplet) has the same chemical composition as a full size conventional ingot but the size has been reduced to less than one mm and the weight has at the same time been reduced from about 400 kg to 0,000004 kg. Reduction of the ingot size is the same as to reduce the segregation problem that limits the strength of the material. The powder is filled into metal cylinders (capsules) sealed by welding after vacuum evacuation. After preheating the cylinders are hot-isostatic pressed to full density billets. The final products are obtained after forging or rolling, heat treatments and final quality inspections.

To achieve good cutting performance from Powder Metallurgy High-Speed Steel, an appropriate hardening response must be provided in heat treatment. Properly performed heat treatment can significantly influence the finite properties of High-Speed Steel, so the heat treatment parameters are chosen depending on the specific properties of the particular tool. The High-Speed Steel heat treatment consists of austenitization in a protective atmosphere, quenching and three high temperature tempering treatments.